| Introduction: Advantage:

* Excellent weather resistance

* Anti-wear & anti-crack

* Line film is densification and not easy to hide the dirt

* Strong UV resistance

* Low VOC and no heavy metal content.

Construction mode includes spraying application and screed application and extruded application.

Contrast of antifouling performance

|

Pollution source |

Pollutants can wipe sexual contrast |

|

MMA two-component anti-fouling marking |

Ordinary products two-component anti-fouling marking |

Thermoplastic pavement marking |

|

sewage |

|

√ |

○ |

|

Catering oil pollution |

√ |

|

× |

|

engine oil |

√ |

○ |

× |

|

2B pencils |

|

× |

× |

|

dust |

√ |

○ |

× |

|

√ Represents the pollution is easy to remove ○ Represents the pollution is not easy to remove × Represents the pollution is hard to remove |

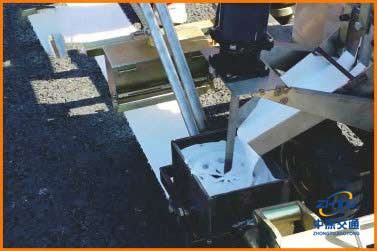

1-Screed application  2-Spraying application

3-The effect of anti-fouling marking

Consumption (Actual consumption depends on the thickness of marking & Roughness of pavement & Local temperature environment )

|

surface temperature 25℃ |

Spraying application |

Screeding application |

Mixed mode |

|

thickness |

0.6mm |

1.2mm |

0.5-0.7mm |

|

Consumption |

|

3kg/㎡ |

Sealing coating: 2kg/㎡

Coating:1kg/㎡ |

|

Hardner |

15g/㎡ |

45g/㎡ |

45g/㎡ |

|

primer |

|

|

150g/㎡ |

Dosage table of curing agent (Used in B component)

|

Paint |

Hardner |

Surface temperature(℃) |

Ratio of BPO |

Surface dry time (Min) |

Curing time (Min) |

|

B component |

White color

powder |

5 |

750g-800g |

25 |

50 |

|

15 |

700g-750g |

20 |

35 |

|

25 |

650g-700g |

10 |

20 |

|

35 |

550g-600g |

8 |

15 |

Technical Data:

·Anti-fouling value: ≤15

·Curing time: ≤15minutes

·Density (g/cm³): 1.7

·Chromaticity performance (white): ≥85

·Abrasion resistance: ≤35mg

·Anti wearing value: 18

Color:White/Yellow /Customize other colors

Typical installation areas:

Urban Rd(very strict to the clean),mining area

The matters needing to attention during the construction

1. Dry & Clean & flat of road surface.

2. Damaged road should be repaired before applying.

3. Before applying,should add the hardner according to the ratio to the MMA two-component (Component B) pavement marking paint,then stir well.

4. Avoid breathing vapors,eyes and skin should not touch the coating.

5. During Construction,eating and drinking and smoking is prohibited.

Attention of construction

1. Clean and dry road surface.

2. Construction environment temperature is about 10℃ to 40℃,surface temperature generally is above 5 ℃.

3. The curing time depends on the consumption of curing agent & the temperature of construction environment,but has nothing to do with the thickness of the coating.

4. Strictly prohibited from direct sunlight during transport and storage,stored in ventilated

and shade and dry place,the storage temperature should be controlled in 0℃ to 40℃.

5. During screeding application,it is recommended that two scraper buckets be equipped for continous replace. |